Studebaker

Six Cylinder Engines

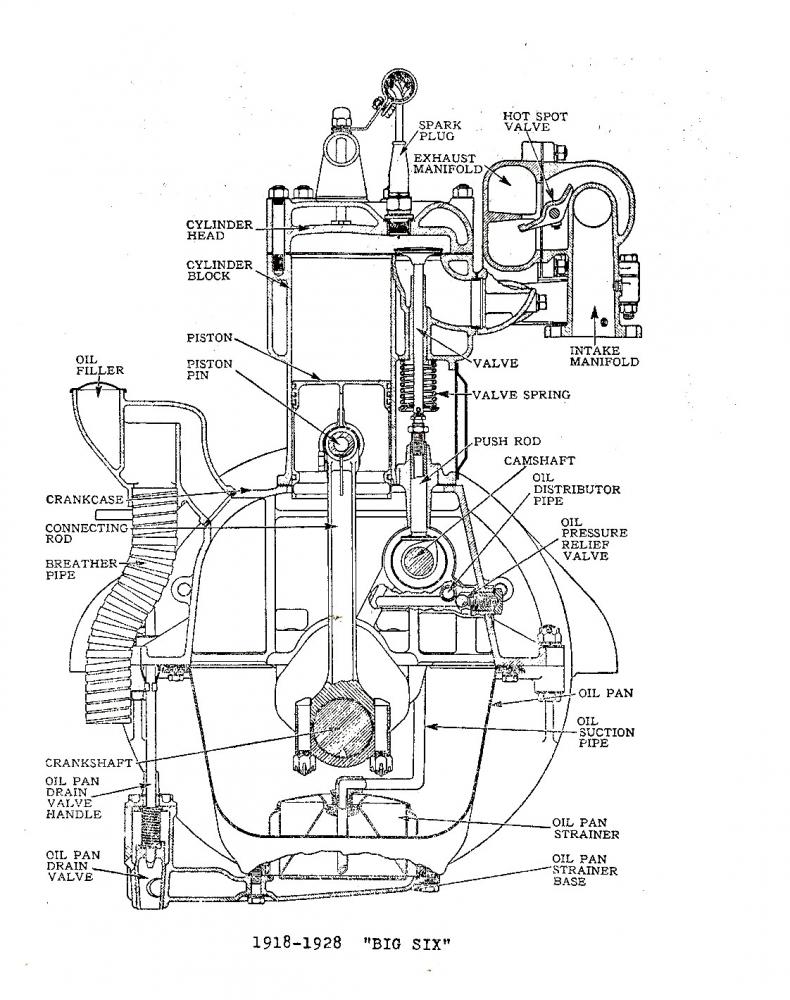

Big Six 1913

to 1928:

Studebaker's

first six, excluding the 1910 Model H Garford, was the rugged 288.6

cubic inch Model E introduced in 1913. The bore was 3.5 inches and the

stroke was 5 inches, making 40 HP. This engine design included

massive bearings, one inch piston pins, four bolt rods and mains, and

fully machined connecting rods. Studebaker's

first six, excluding the 1910 Model H Garford, was the rugged 288.6

cubic inch Model E introduced in 1913. The bore was 3.5 inches and the

stroke was 5 inches, making 40 HP. This engine design included

massive bearings, one inch piston pins, four bolt rods and mains, and

fully machined connecting rods.

Big Six

Enhancemen:

1916: the bore was increased to 3 7/8 inch, resulting in 353.8 cubic

inches, making 50 HP.

1918: detachable head was introduced, and HP was increased to 65.

1925: compression was increased from 4.1 to 4.45, increasing the HP to 75,

full pressure lubrication is provided to the mains, rods, and

camshaft bearings. Main bearing journals are increased by 5/16 of an

inch.

Side Bar:

For

1918 & 1919, the 288.6 cubic inch, 3.5 inch bore (Big Six) was

re-introduced as the Light six, not to be mistaken with the “new”

207.1 cu. in. Light Six of 1920.

The

1913, 25 HP four, used the same bore and stroke as the Model E Six,

resulting in interchangeable pistons, rods, valves, and tappets. The

bore of the four was increased in size in 1916 to 3 7/8 inch, just as

the “Big Six” was, keeping with the theme of common parts across

both the four and six engine design.

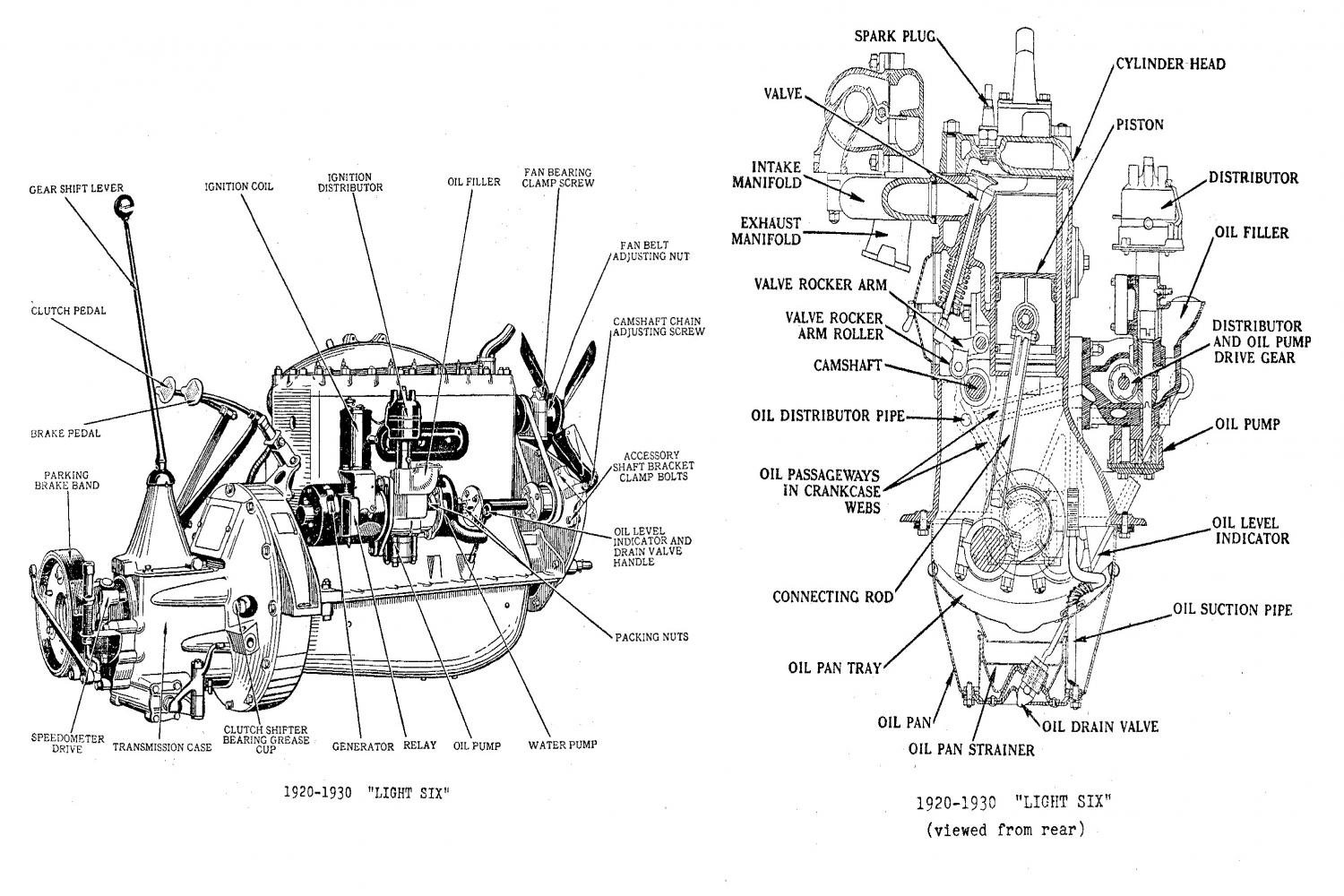

Light Six –

Standard Six 1920-1930:

Production

of the 207.1 cu. in. Light Six engine began on April 30th,

1920, the four being discontinued the year before. It takes the

place of the already existing “Light Six” 288.6 cubic inch engine

which is renamed the “Special Six”. This provides Studebaker

with three six cylinder engine choices to fit it's three car lines;

Big Six, Special Six, and Light Six going into the 20's. Production

of the 207.1 cu. in. Light Six engine began on April 30th,

1920, the four being discontinued the year before. It takes the

place of the already existing “Light Six” 288.6 cubic inch engine

which is renamed the “Special Six”. This provides Studebaker

with three six cylinder engine choices to fit it's three car lines;

Big Six, Special Six, and Light Six going into the 20's.

In

contrast to the interchangeable parts between the larger two engines,

this engine is a unique new design. Fitted with inclined valves with

bell-crank roller tappets, aluminum cylinder head, integral intake

manifold, and fully machined crankshaft and rods. It used an

accessory shaft, chain driven, which provided power for the water

pump, oil pump, generator, distributor, and fan. Lubrication is full

pressure to the main bearings, cam bearings, and timing chain and

splash to the rods. This engines bore is 3 1/8 inches and stroked at

4 ½ inches, making 40 HP at 2000 RPM.

Manufactured

from 1920 to 1930, the engine is used in the Light Six, Standard Six,

Dictator Six, Commander GJ, and the Model 53 Erskine.

Enhancements:

1925

(Standard Six): the bore is increased to 3 3/8 inch and the

compression ratio is increased from 4.38 to 4.5, resulting in 50 HP

at 2200 RPM from it now 241.6 cubic inches. The head is now cast

iron and the block is modified adding intake ports next to the

exhaust ports. Full pressure lubrication is added.

1928,

(Dictator): HP increased to 67 from the same 241.6 cubic inches.

1929-30

(Commander GJ): engine stroked at 4 3/8 inch – 248.3 cubic inches

making 75 HP.

1930,

(Dictator): engine stroked at 4 1/8 inch – 221.4 cubic inches,

making 68 HP, (Last Dictator Six until 1934).

1930,

(Erskine – Studebaker Six): bore reduced to 3 ¼ – 205.3 cubic

inches, making 70 HP.

1931-33,

(Studebaker Six): the engine was farther refined (bore little if any

resemblance to the existing 205.3) ,keeping the same cubic inches,

but with an entirely different layout. The accessory shaft was

eliminated. The water pump moved to the front, generator moved to

the left front - driven by a crankshaft pulley, intake, exhaust, and

carburetor moved to the right side - requiring a completely new block

and head. Distributor moved to the left side driven off the

camshaft. The rods, crankshaft, pistons, valves, and other internals

were all that were retained. These changes set the pace for

Studebaker Six engine design for years

to come.

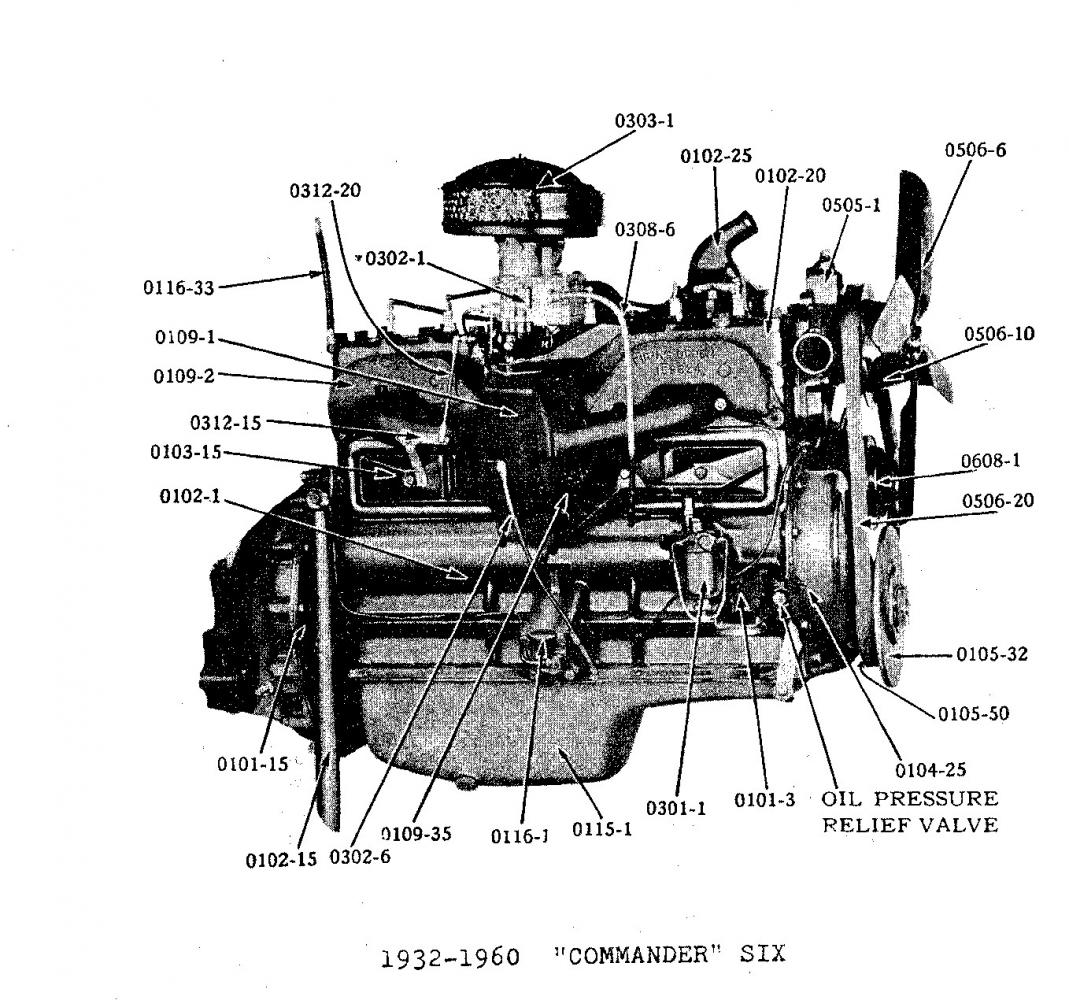

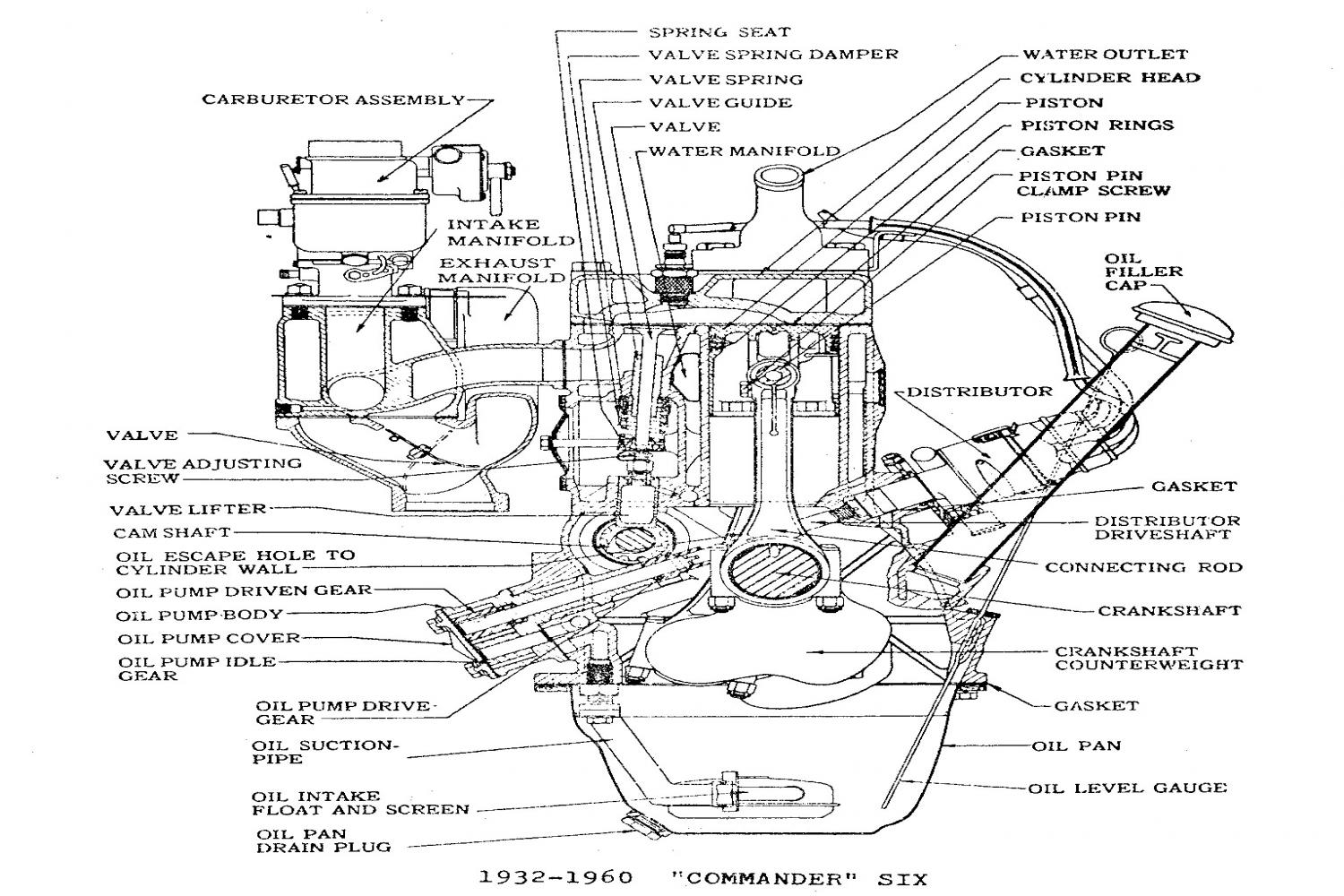

Rockne –

Commander – Dictator Six 1932 – 1960

First

designed to power the 65 Rockne (1932), having a 3 1/8 inch bore and

4 1/8 inch stroke at 189.8 cubic inches, it developed 66 HP at 3200

RPM. It used a counter-weighted, dynamically balanced, and

rifle-drilled crankshaft; vibration damper; silent chain camshaft

drive; high velocity cooling; and electro-plated pistons; all typical

fine car features of the day. First

designed to power the 65 Rockne (1932), having a 3 1/8 inch bore and

4 1/8 inch stroke at 189.8 cubic inches, it developed 66 HP at 3200

RPM. It used a counter-weighted, dynamically balanced, and

rifle-drilled crankshaft; vibration damper; silent chain camshaft

drive; high velocity cooling; and electro-plated pistons; all typical

fine car features of the day.

Enhancements: Enhancements:

1933

(Rockne 10): compression raised to 5.5 to 1 increasing the HP to 70

at 3200 RPM.

1934-35,

(Dictator): gear driven valve train, down-draft carburetor, increase

bore to 3 ¼ inch – 205.3 cubic inches, making 88 HP.

1936-37,

(Dictator): increase stroke to 4 3/8 – 218.8 cubic inches, making

90 HP.

1938-41

1947-48 (Commander): increase bore to 3 5/16 – 226.2 cubic inches,

making 90-94 HP

1949-50

(Commander): increase stroke to 4 ¾ – 245.6 cubic inches, making

100HP.

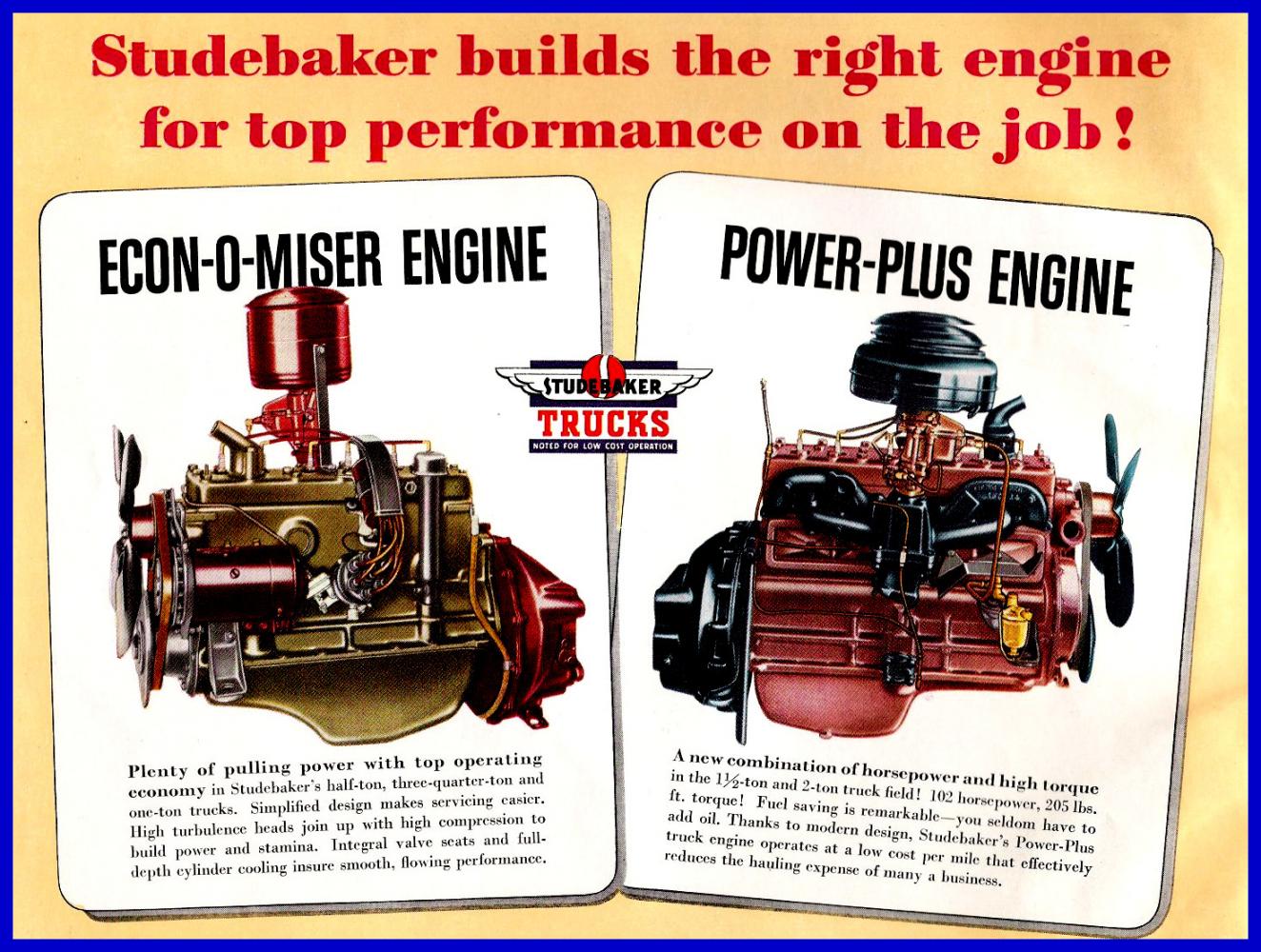

This

basic engine configuration was also used on the K, L, M, R, and E Series

trucks from 1938 to 1960, mostly in the 226 cubic inch and 245 cubic

inch versions. The 249 cubic inch version of this engine finished in

1960 at 118 HP, producing 204 foot pounds of torque at 1400 RPM. The Power-Plus Engine in the ad below.

The Power-Plus is the Commander engine (above)

The Econ-O-Miser is the Champion engine. (Below)

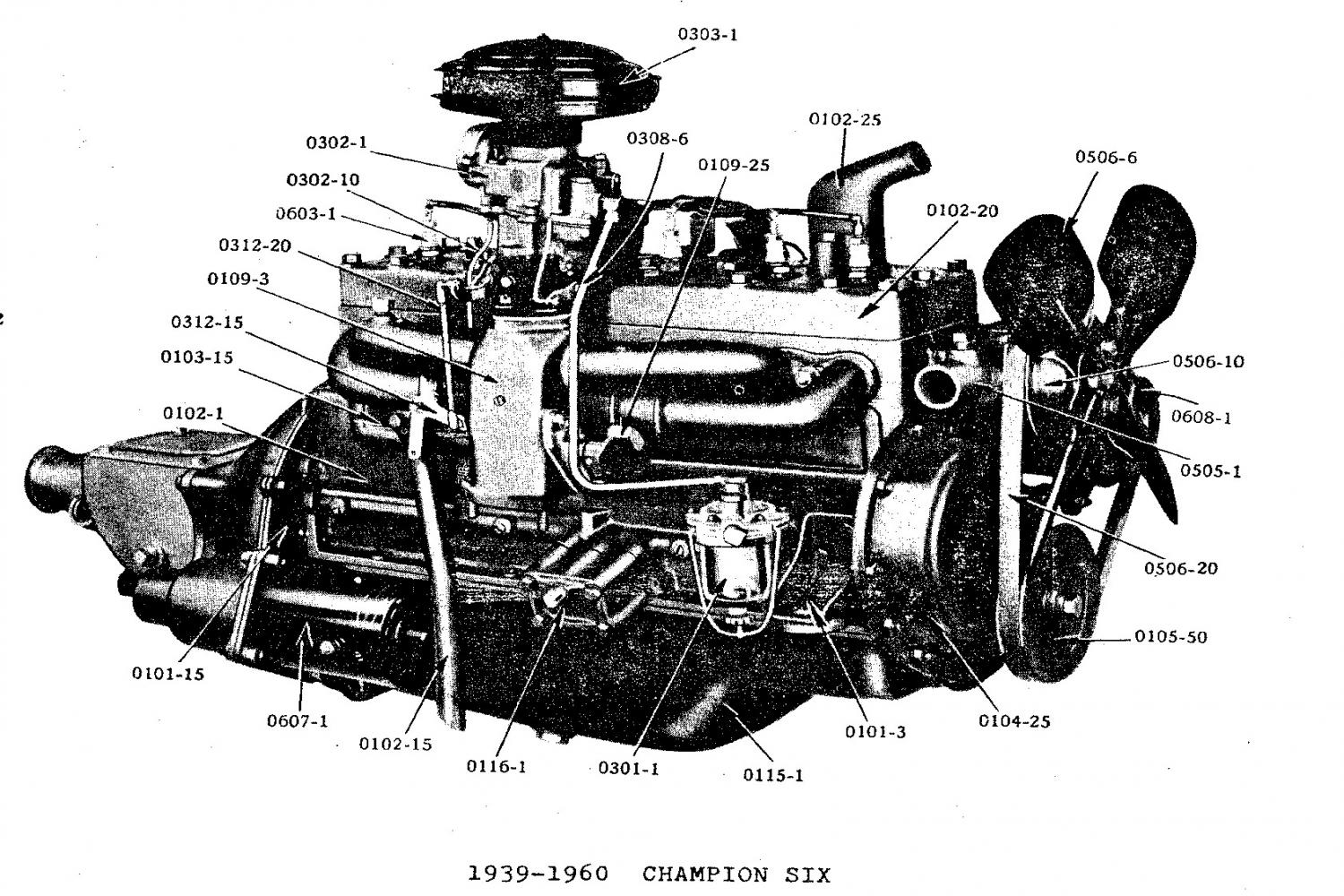

Champion Six

1939 -1964

Free

of the need to use this engine in other heavier cars or trucks, the

Champion engine was designed with nearly zero chance of increasing

the bore size. In it's original configuration of 3 inch bore and 3

7/8 stoke – 164.3 cubic inches, it produced 78 HP. This fresh new

design was on average 170 to 250 pounds lighter then the

competition's sixes and developed 17 to 24 percent more horsepower

per cubic inch then the competition. It feature a 3/16 inch overlap

of the main and connecting rod bearings; full pressure lubrication;

sealed water pump; and a one-piece manifold. Free

of the need to use this engine in other heavier cars or trucks, the

Champion engine was designed with nearly zero chance of increasing

the bore size. In it's original configuration of 3 inch bore and 3

7/8 stoke – 164.3 cubic inches, it produced 78 HP. This fresh new

design was on average 170 to 250 pounds lighter then the

competition's sixes and developed 17 to 24 percent more horsepower

per cubic inch then the competition. It feature a 3/16 inch overlap

of the main and connecting rod bearings; full pressure lubrication;

sealed water pump; and a one-piece manifold.

Enhancements:

1941-42

1946-49: increase the stroke to 4 inches – 169.6 cubic inches

making 80 HP.

1950-54: HP increased to 85.

1955-58: stroke increased to 4 3/8 inches – 185.6 cubic inches making 101 HP

the engine is painted silver instead of olive drab.

1959-60: reduced stroke back to 4 inches – 169.6 cubic inches making 90 HP.

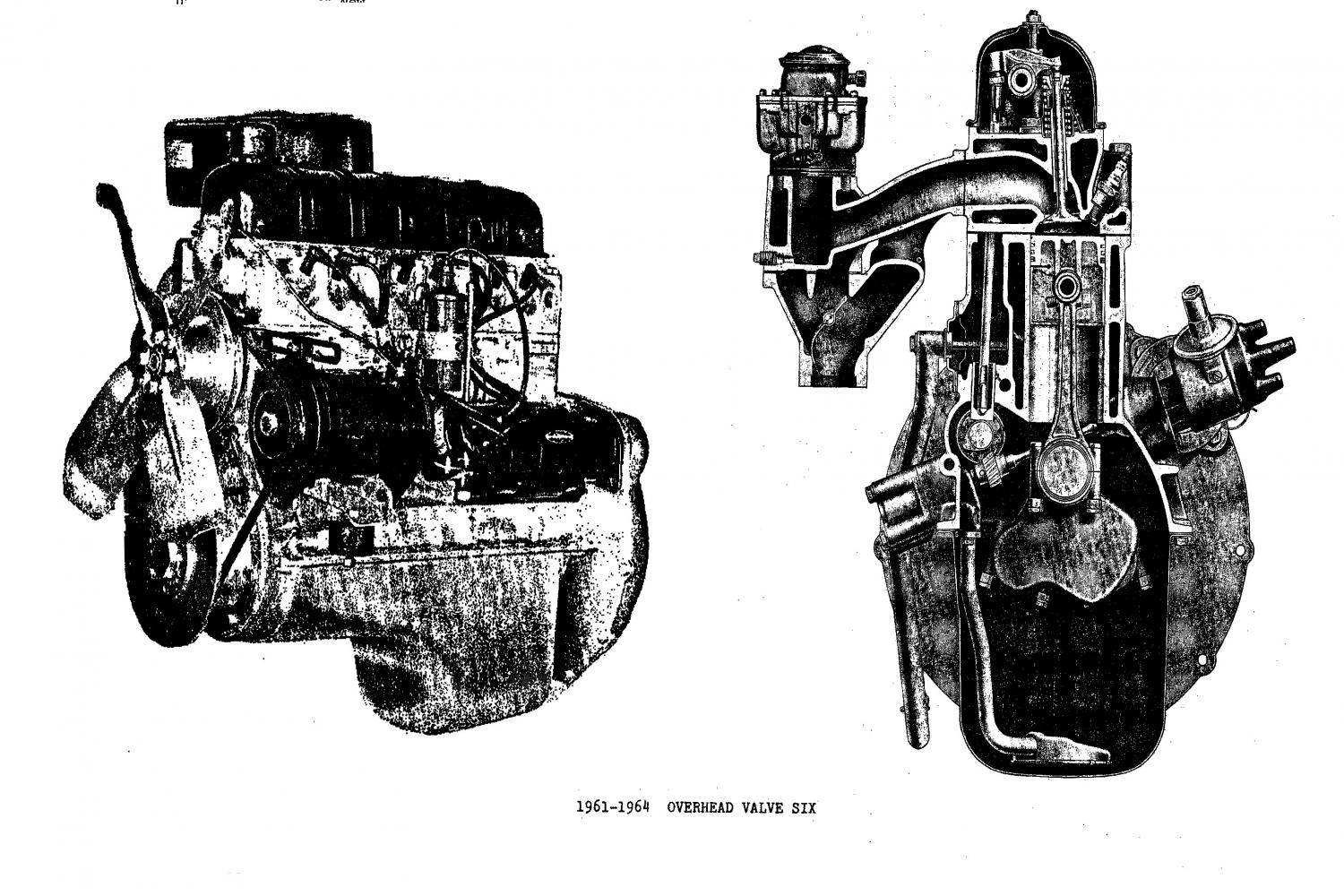

Champion

Overhead Valve Six 1961 – 1964

In

1961 the L-head 169.6 cubic inch engine was converted to overhead

valve, improving the breathing through larger valves and better

manifolding. The new “Skybolt Six” was 112 HP and 154 foot

pounds of torque. In

1961 the L-head 169.6 cubic inch engine was converted to overhead

valve, improving the breathing through larger valves and better

manifolding. The new “Skybolt Six” was 112 HP and 154 foot

pounds of torque.

Enhancements:

- Full

flow oil filter 1962

- Slipper

pistons late 1963.

Summery

In

Studebaker's fifty three years of production, only five basic six

cylinder engine designs were utilized.

Credit: A lot of the information and photos come from a Turning Wheels article by H.L. Beckman. Other information came from "Studebaker the Complete Story" by William Cannon & Fred Fox. |