Credit:

Hot Rod Magazine, August 1955

Packard's

bold bid for power includes a radical new chassis and the industry's

biggest engine. Packard's

bold bid for power includes a radical new chassis and the industry's

biggest engine.

The

veil of secrecy that shrouded the new Packard V8 has been surpassed

only by the Iron Curtain. Usually, new automotive developments are

released to members of engineering groups and the press some time

before the cars fill the showrooms, but this year Packard withheld

specific information of two very significant innovations. Meanwhile,

a few expert rumormongers had a field day. According to them, the new

Packard V8 engine was a 400-cubic inch, two- cammed affair with an

aluminum block. The actual result is slightly less spectacular, but

nonetheless quite worthy of a detailed discussion.

In

1946, Packard instituted an engine development program to explore the

possibilities of new and novel designs suitable for future production

as successors to the venerable straight eight. To be sure, many

unusual designs were tested and evaluated, as were new methods and

materials (including aluminum cylinder blocks). By 1949, most of the

details of the new Packard engine were established; that is, nearly

everything except the piston displacement which was originally set at

269 cubic inches. The leaps and bounds by which other manufacturers

increased piston displacement, power and torque prompted Packard

engineers to reconsider and redesign, so they wouldn't be caught

flat-footed with an engine that would be under powered to sell the

increasing numbers of performance-conscious buyers. So they went to

the other extreme and made the production engines big, with

provisions for going bigger whenever the need arises.

Currently,

the Packard Division of the newly formed Studebaker-Packard

Corporation is supplying 320-cubic inch V8 engines for both the '55

Hudson "Hornets" and the Nash "Ambassadors." Basically,

these, are "detuned" versions of the 320-cubic inch Clipper

engine,

which, in turn, is a smaller edition of the engine used in the

Clipper "Custom," Packard and the Packard "Caribbean"

models. Packard engineers have never shied away from building

engines of mammoth proportions and their latest effort is

automatically a unanimous choice for the world-famous (but mythical)

organization, "There Ain't No Substitute for Cubic Inches"

Club, of which I modestly proclaim I am mythically president. This

352-cubic inch monster has a four-inch bore and a 3 1/2-inch stroke,

which results in the favorable stroke/bore ratio of .88 to 1. The

maximum advertised brake horsepower is 260 obtained at an engine

speed of 4600 rpm and maximum advertised torque is 355 pounds-feet

between 2400 and 2800 rpm. The same size engine in the Clipper

"Custom" produces 245 brake horsepower at 4600 rpm and 355

pounds-feet of torque at 2600 rpm. The smaller 320-cubic inch engine

(3 13/16-inch bore, 3 1/2-inch stroke) in the Clipper "DeLuxe"

and "Super" series yields 245 brake horsepower at 4600 rpm

and 325 pounds-feet of torque at 2600 rpm. Both the Hudson and Nash

versions put out 208 brake horsepower at 4200 rpm and 300 pounds-feet

of torque at 2300 rpm. These values were obtained under the

following conditions: The water, fuel and oil pumps were connected

and operating; the generator was rotating but was not charging; the

spark advance was manually adjusted for best torque; dynamo-meter

exhaust collectors were used; intake manifold heat was blocked off;

fuel was 93 octane Research gasoline; no fan or carburetor air

cleaner was used. The dynamo-meter figures were represent "as

installed" values. With the engine in the car and with the

stock exhaust system hooked up, an air cleaner and fan installed, a

"hot" intake manifold and a load applied to the generator,

plus under- the-hood temperatures of around 100 degrees F., the power

and torque will drop off on an average of about 14 and 12 per cent,

respectively. Even so, the big Packard has the edge on all

competitors in all departments; the displacement is 3.2 per cent

larger than its closest rival, the advertised power is four per cent

higher and the advertised maximum torque is 2.9 per cent more. This

engine also scores in the matter of engine weight, the whole issue

with all accessories except the air cleaner, tipping the scales at

698 pounds. The 210-pound cylinder block is cast with the usual 90-

degree span between cylinder banks from close-grained alloyed iron. The blocks for both engine sizes are identical except for the

cylinder bore diameters and the coring of the cylinders. The upper

half of the bell housing is an integral part of the block. Five

transverse bulkheads separate the cylinders of each bank and are used

as supports for both the crankshaft and the camshaft. The main

bearing caps are located 1/4 of an inch above the oil pan surface in

longitudinally broached recesses. The cylinders are surrounded by

full-length water jackets, except at the inboard sides, where the

jacket length is reduced to make room for the valve lifter bosses and

two longitudinal oil galleries. Distortion of the cylinder bores is

minimized by tying the cylinder head screw bosses into vertical ribs. The center- to-center distance between adjacent cylinder bores is

five inches, which leaves a gasket seal.

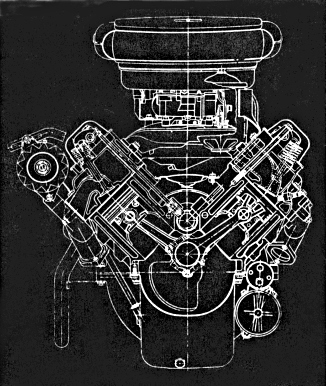

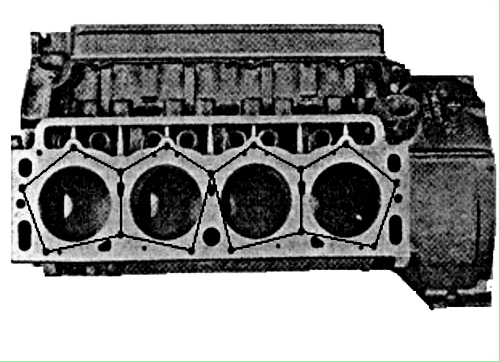

Transverse,

left, and longitudinal sections of the Packard V8

This

little feature could and should be used by a few other manufacturers. This dimension also allows the bore diameters to be enlarged at a

future date without scrapping the existing tooling. All that is

required is a relatively simple and inexpensive change in the coring

of the cylinders. Sufficient space in the underside of the block has

been provided for a substantial increase in crankshaft stroke, when

the need arises, without interference with the existing block casting

or other parts. The overall length of the cylinder block is 27 3/4

inches. From all outward appearances, the block could be safely

rebored to 4 1/8 inches with no particular danger from cylinder

distortion or overheating; on Packard and Clipper "Custom"

blocks, that is. The 3 13/16 inch bores of the Clipper "DeLuxe"

and "Super" blocks, as well as those of the Hudson and

Nash, could be bored to a maximum of 3 15/16 inches with reasonable

safety. Packard engineers went to considerable lengths to evaluate

the relative merits of forged versus cast crankshafts. According to

their findings, a steel casting provides a sufficiently high modulus

of elasticity as well as material density to effect a lighter

crankshaft without sacrifices in rigidity or stiffness. Also, a

casting permits the counterweights to be more favorably disposed for

balancing effectiveness, as well as coring of the crankpins to reduce

the amount of unbalance and, consequently the size of the

counterweights. The finished Packard V8 crank is a heat-treated

alloyed steel casting that weighs 56 pounds. The five main bearing

journals are ground to a diameter of 2.500 inches and the crankpins

are 2.250 inches in diameter. These dimensions are well within the

realm of design conservatism shown elsewhere in the engine. With the

3 1/2 inch stroke, an overlap of 5/8 of an inch is obtained between

the crankpins and adjacent main bearing journals, which materially

contribute to the torsional stiffness of the crank. The total

connecting rod effective bearing area is 52.8 square inches and the

total main bearing effective area is 38.6 square inches. A

non-bonded rubber harmonic balancer is placed at the nose of the

crank and is effective in reducing the amplitude of torsional

vibrations. The balancer is integral with the crankshaft pulley

assembly. Fore-and-aft crankshaft thrust loads are taken by the

flanged rear main bearing. The main bearings are copper-lead, while

connecting rod bearings are lead-babbitt, and both are of the

steel-backed replaceable insert type. Both bearing materials are

completely compatible with the heat-treated but unhardened steel

crank. Each connecting rod has its own bearing that is locked in the

rod and the crankshaft is drilled to oil each of the two bearings on

the crankpins. The healthy appearing connecting rods are drop

forgings made from SAE 1041 steel. The beam is of "H"

section design and the rods have a center-to-center length of 6 23/32

inches. Two specially formed high tensile steel bolts locate and

secure the rod cap to the rod. A groove is machined at the juncture

of rod and cap to provide lubrication from the rod bearings to the

cylinder walls on the opposite bank. Balancing lugs form integral

parts of the rod assembly, one lug at each end. A bronze piston pin

bushing is pressed into the small eye of the rod and is bored to give

.0002 of an inch clearance between the bushing and the pin. The

connecting rod assembly has undergone very severe testing at loads

and speeds, far in excess of those encountered in any type of driving

conditions. Each rod assembly weighs one pound 10 ounces. Aluminum

alloy "autothermic" pistons are used in which steel tension

members control the amount and direction of piston expansion. The

pistons "nest" about the crankshaft counterweights at the

bottom of the stroke, which necessitates a "slipper" type

skirt. Crown thickness of the flat-topped piston is .280 of an inch. Three ribs extend from the piston pin bosses to the crown for pin

boss rigidity. The .980 of an inch diameter by 3 1/4 inch long

piston pin is a full floating affair that is retained in the piston

by snap rings and grooves in the pin bosses. The pin material is

heat-treated SAE 1117 steel. The piston pin bores are offset 1/16 of

an inch in the direction of the major thrust face. Pistons are tin

plated to minimize "scuffing" during the initial break-in

period. Piston weight is one pound six ounces. Two compression

rings and one oil ring are used, all of which are located above the

piston pin. The alloy cast iron compression rings are 5/64 of an

inch wide with a radial thickness of .200 of an inch and have tapered

faces. The top ring is chrome plated to a thickness of from .004 to

.007 of an inch for longer, life and freedom from the effects of high

temperatures and corrosive gases.

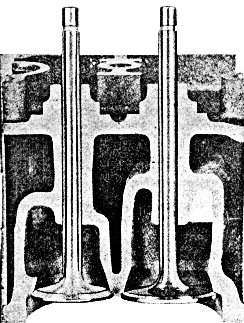

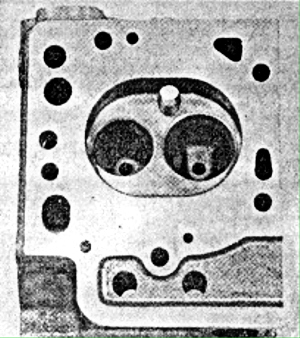

Cutaway

head shows generous passages, valve sizes and integral seat and guides.

The

alloy cast iron oil ring is of open slot design and measures 3/16 of

an inch in width with a radial thickness of .166 of an inch, and uses

a polygonally shaped light spring steel expander. The hardenable

alloy iron camshaft is driven by a one inch wide timing chain and

sprockets on the crank- and camshafts. The cam is supported in the

block by five removable steel-backed babbitt-coated bearings. The

cam lobes are ground with a taper of six minutes and are positioned

1/16 of an inch in back of the valve lifter centers to avoid lifter

overrun and insure positive lifter rotation. A helical gear, located

ahead of the rear bearing journal, is an integral part of the

camshaft and is used to drive the distributor. Hydraulic valve

lifters are used in all models, the bodies of which are Lubrite

coated hardenable iron. The lifter faces are ground to a spherical

radius of 30 inches and the lifter body diameter is .904 of an inch.

Lubriting the lifters and phosphate coating the camshaft is said to

minimize initial break-in wear, which seems to be the period when cam

and lifter wear is the most severe. In line with this, it is

interesting to note that, although the cams in all the Packard

engines are, to all intents and purposes, identical, cast steel

camshafts are specified for the engines supplied to Hudson and Nash. Even more interesting would be a comparison of the wearing qualities

of the two different camshaft materials, after each has been

subjected to long periods of operational service. But this we won't

know for a while. The cylinder head castings are made from the same

material as the block. They are interchangeable, left to right, and

each head weighs 64 pounds. Very generous water jacketing has been

provided around the ports, valves, spark plugs and combustion

chambers. Each head is located on the block by two dowels and is

secured by 15 cap screws, 7/16 of an inch in diameter, in a pattern

that surrounds each cylinder with five cap screws. Cylinder head

gaskets are of the embossed steel type, .025 of an inch thick. After

playing with many different combustion chamber configurations,

Packard chose the elliptically shaped, high turbulence "wedge"

type chamber. Tests have shown that, at compression ratios of 12 to

1, this design provides a low burning rate of the fuel/air mixture

charge and avoids a rapid pressure rise, thereby minimizing

combustion roughness, and the chamber is quite insensitive to

combustion chamber deposits usually incurred during low speed, light

load operation. "Quench" and "squish" areas,

formed by a .045 of an inch piston-to-cylinder head clearance, cover

20 per cent of the total piston area. Each combustion chamber is

fully machined, which makes for a consistent compression ratio for

all cylinders. The valve head diameters are unusually large for this

type of combustion chamber, being 1 15/16 inches for the intake

valves and 1 11/16 inches for the exhausts. This accounts for what

appears to be a slight "shrouding" of the valves at the

ends of the combustion chambers. The spark plug is located about 3/8

of an inch from the lateral axis of the cylinder bore toward the

intake valve on the deep side of the chamber. Due to the angular

location of the plug in the head, a counter-bored passage connects

the firing end of the plug with the main combustion chamber cavity. The present compression ratio of the Clipper and Packard engines is a

conservative 8 1/2 to 1, while the Hudson and Nash engines have an

even more conservative ratio of 7.8 to 1. If one chose to use the

heads of the 320-cubic inch Packard engine on the 352-cubic inch

engine, a compression ratio of 9 1/4 to 1 would be obtained, which

would be the upper limit for use with presently available gasolines. Or the heads may be milled .050 of an inch on the 352-cubic inch

engine for the same result. The same amount milled from the heads of

the Packard 320-cubic inch engine would result in a compression ratio

of 9.1 to 1. To obtain a compression ratio of 7.8 to 1 on the Hudson

and Nash, the heads from the 352-cubic inch engine are used. By

milling the Hudson and Nash heads .065 of an inch, the compression

ratio will be 8.7 to 1. When and if the heads are milled, each

side-of the intake manifold should be milled the same amount as the

heads to maintain correct intake port alignment. Also, the push rods

should be shortened by the amount milled from the heads. As future

fuels improve, it becomes a very simple matter of a coring and minor

tooling change to increase the compression ratio of the Packard

engine, which would undoubtedly be accomplished by lowering the

"roof" of the wedge type chamber.

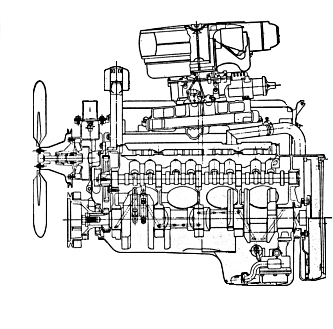

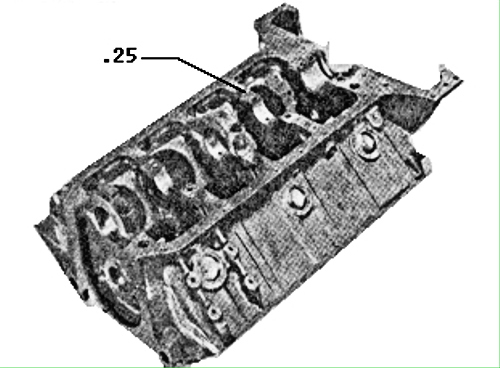

Left View: Bottom

of sturdy Packard V8 block has broached recesses for the positive

location of the five main bearing caps.

Right View: Cylinder

head cap screw pattern and the widely spaced bores provide a good

gasket seal with minimum block distortion.

As

previously mentioned, the valve sizes are quite generous, but much

more important for a high volumetric efficiency, the ports are

positively huge, especially on the intake side. As in other

comparable designs, the intake ports of the Packard cylinder heads

are rectangular in shape and arranged in pairs. Exhaust passages in

the heads have been laid out so that the two end cylinders of each

bank have individual ports, while the two center cylinders of each

bank discharge exhaust gases into common ports. Each center port has

a continuation extending upward and into the intake manifold pre-heat

chamber. Both intake and exhaust valve guides are an integral part

of the heads, which materially aid in reducing valve temperatures,

not only at the valve stems but at the seats as well. In fact, tests

involving the use of integral valve guides have shown that valve head

temperatures can be lowered as much as 200 degrees F., with a

corresponding reduction of valve stem temperature of 100 degrees F.,

as compared to the diminishing practice of using pressed-in guides,

which erect a thermal barrier despite the similarity of metals and

the proximity of the guides to the guide bores in the heads. Intake

valves are made from Silichrome number one steel, while the exhausts

are made from number 2112 austenitic steel. The valve seat angle is

30 degrees on the intake and 45 degrees on the exhausts. The

longitudinal axes of the valves form an angle of 12 degrees with the

longitudinal axes of the cylinder bores. The valves are retained by

conventional tapered split keepers, retainer washers and single valve

springs. In an effort to obtain a satisfactory valve motion in the

interests of good engine performance and yet not overload the nose of

the cam lobes, the Packard cam lobe shape results in a relatively low

rate of valve acceleration together with a low valve spring rate. The valve timing is as follows: Intake opens 14 degrees before top

center, closes 56 degrees after bottom center, duration 250 degrees,

lift at valve .375 is of an inch. Exhaust opens 52 degrees before

bottom center, closes 18 degrees after top center, duration 250

degrees, lift at valve .375 of an inch. The valve spring load is 82

pounds with the valve seated and 165 pounds with the valve open. The

rocker arms are cast pearlitic malleable iron with flame hardened

ends.

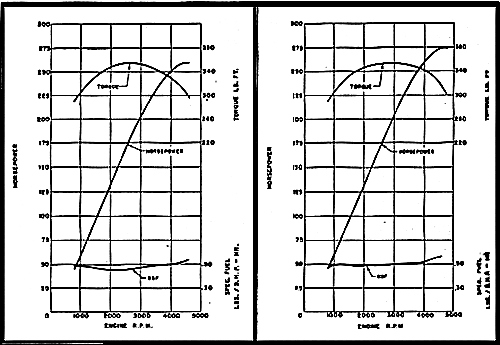

Brake

horsepower, torque and brake specific fuel consumption curves of the

standard 352-cubic inch Packard V8 engine, left, and the dual

four-throat "Caribbean," right.

These

are located on a single longitudinal rocker shaft for each head,

which is secured to the head by four rocker arm stands and four cap

screws. The rocker arm lift ratio is 1.6 to 1. Push rods are of

steel tubing with an outside diameter of 3/8 of an inch and a wall

thickness of .065 of an inch. These contain hardened steel tips that

arc ground to a spherical radius of 1/4 of an inch and are pressed

into the open ends of the push rods. Hydraulic valve lifter

"pump-up" speed is about 5100 rpm. Hm-m-m. With a little

intelligent work on the valve train, together with faster valve

action and more lift, one could more fully utilize the inherently

good "breathing" capacity of these engines. This might

require different cam and lifter material though. In the carburetion

department, there seems to be a great divergence of the engineering

minds. Hudson and Nash specify a single Carter WDG-223I-S two-throat

carburetor while the Clipper "DeLuxe" and "Super"

models call for a single Carter WCFB-2232-S four-throat. Both

Clipper "Customs" and Packards use a single Rochester '4GC

four-throat. The "Caribbean," Packard's answer to a

certain earth-bound space ship, employs two of the above Rochesters

on a well-designed, balanced intake manifold, which, incidentally,

will fit the other engines of the species. All of the carburetors

contain a thermostatically operated automatic choke which receives

heat from the intake manifold "stove." The intake

manifolds of the series are made from cast iron and have been

symmetrically designed in an attempt to equalize the lengths of the

passages. The carburetors receive fuel under a pressure of from 3

1/2 to 5 1/2 psi from a mechanical pump located on the right side of

the engine front cover. The pump is driven by a chrome plated,

hardened stamped steel eccentric that is bolted onto the front of the

camshaft sprocket. The unbalanced condition caused by the eccentric

is compensated for by the nonsymmetrical openings in the camshaft

sprocket. The fuel pump is one component that has been simplified in

the Packard design, for it no longer contains an integral vacuum

booster pump. But you'd never guess where said vacuum booster is

hiding. It's in the pan! Exhaust gases are collected by cast iron

manifolds that are positioned so that one won't get scorched changing

spark plugs on a hot engine. With the standard exhaust system, the

left-hand manifold connects to a two-inch diameter crossover pipe

that passes beneath the engine and joins to a 2 1/4-inch diameter

header pipe that extends to a reverse flow muffler. Tailpipe

diameter is two inches. With the optional dual' exhaust layout, the

header pipe diameter is two inches and the tailpipe diameter is 1 3/4

inches. Positive lubrication of the Packard engines is handled by a

spur gear type pump assembly with a built-in pressure relief valve. The pump is driven by an intermediate shaft that couples with the

distributor drive gear. Oil entering the pump through a screened

floating pickup is directed through a rather complex system of

galleries, drilled passages and headers to all main, connecting rod

and camshaft bearings, as well as valve lifter guide bores, rocker

shafts and arms, the timing chain and fuel pump eccentric. Other

parts are lubricated by splash or drain-back oil. A very sensibly

placed partial flow type oil filter is located on top of the engine

at the left front. This little gem of forethought makes changing the

filter cartridge an absolute joy rather than a tragedy. A constant

system pressure of 50 psi is maintained by the pressure' relief valve

under all normal operating conditions. The oil pump assembly isn't

complete without an eccentric vane-type vacuum booster pump for

windshield wiper operation under low vacuum conditions. The pump

performs double duty when the engine is idling because the pump

exhaust creates a pressure differential in the crankcase, which aids

in the circulation of air through the engine. To satisfy both the

present and future electrical requirements, particularly those of the

ignition and the starter motor, Packard has adopted a 12-volt system. Auto-Lite electrical systems are used on the small displacement

engines, while the big 'un employs Delco-Remy. The ignitions contain

centrifugal advance mechanisms as well as vacuum advance boosters. The starter motor and solenoid assembly is located at the rear of the

engine on the lower left side. The ignition is positioned at the

back of the engine to the left of center and is driven by a helical

gear that matches the gear on the camshaft. The pressurized cooling

system makes use of a single, high capacity centrifugal type pump

that is driven via pulleys and a 3/8 of an inch V-belt from the

crankshaft. The pump is mounted in a casting that resembles an

intake manifold for some strange four-banger. Coolant enters the pump

from the single lower radiator outlet, through an oil cooler for the

radiator. The heat rejection of the new engines to the coolant has

been reduced by about 21 per cent, as compared with the '54 straight

eight, which, in part, attests to the increased thermal efficiency of

the V8's. The method of balancing the engines is also of some

interest. Before assembly, all of the rotating and reciprocating

parts are individually balanced. This group includes the crankshaft,

connecting rod assemblies, piston assemblies, flywheels and harmonic

balancers. After the engine is put together, it is transferred to a

special balancing machine, which motors the engine sufficiently to

indicate the amount and location of unbalanced forces. The machine

automatically stops the engine at this point and the indicated

unbalance is compensated for by automatically drilling into the

crankshaft pulley and welding a slug onto the flywheel. Packard

claims that the stack-up of balancing tolerances that occurs during

engine assembly is reduced to no more than 1/4-inch-ounces by this

method. Could be, but I'd like to know how the balancing machine

compensates for the unbalanced forces that are absorbed by engine

friction while the engine is being motored. Oh, yes, almost forgot. The 352-cubic inch "Caribbean" engine is rated at 275 brake

horsepower at 4800 rpm and 355 pounds-feet of torque at 2800 rpm. This engine uses the previously mentioned double four-throat

manifold, carburetors and dual exhausts and is the most potent

automotive engine currently being produced in this country.

Fully

machined combustion chamber has been tested at compression ratio of

12:1.

|